Circular Fashion News / May 26: New EPR fee demands, study on scaling polyester recycling, DPP launches, Miu Miu's upcycled collection

Your weekly edit of what has happened in the circular fashion space. Last week featured new EPR fee demands, Digital Product Passport pilot launches, and a key study on scaling polyester recycling.

Welcome to reading a weekly recap of circular fashion news! Some of last week’s highlights in the circular fashion industry included:

WRAP warned of a potential collapse in the UK’s used textile system, echoing similar warnings previously issued in the EU

Sparxell received a €1.9 million grant from the European Innovation Council

Luxury brand Gabriela Hearst launched a made-to-order suiting service

Ask Scandinavia partnered with Tree to launch their Digital Product Passport, IoDF is launching their DPP solution, and the Bangladesh garment industry is piloting in the space

A couple of weeks ago, the EU approved a unified way of measuring the environmental impacts of textiles and apparel

Upcycling company Losanje won the ANDAM Fashion Innovation Award 2025

A new study was released on how to scale polyester textile recycling across Europe

WRAP: The UK’s used textile system is at risk of collapse and soaring costs

UK textile collectors and sorters currently spend £88 million annually to collect and process worn-out clothing. Now, WRAP (the Waste and Resources Action Programme) warns that this cost could rise significantly, and that the entire system risks collapse without urgent intervention.

According to WRAP, if no funding or systemic support is introduced, the failure of the UK’s textile sorting and reuse infrastructure could result in an extra £64 million per year in landfill and incineration costs for local authorities. By 2035, the total cost burden could reach up to £200 million annually.

Similar warnings have previously been raised in the EU, where the cost of handling low-value used textiles has increasingly shifted from producers to local systems. As one of the key solutions, both WRAP in the UK and stakeholders across the EU have called for the implementation of Extended Producer Responsibility (EPR) schemes. These would shift the financial burden of managing used textiles from local authorities and charities to the producers.

H&M Global Change Awards 2025: Biodegradable dyes, recycled textile waste, and upcycling designs

The H&M Foundation has announced the ten winners of the Global Change Award 2025. Each recipient will receive a €200,000 grant and join the yearlong GCA Changemaker Programme.

Among the selected initiatives are The Revival Circularity Lab in Ghana, which recycles and downcycles textile waste from the Kantamanto market; Loom, a platform that connects individuals with upcycling designers; Renasens, offering a waterless and chemical-free textile recycling method; Brilliant Dyes, developing biodegradable dyes from algae; and CircularFabrics, recovering high-quality nylon from blended textile waste with their NYLOOP® technology.

New section! This section highlights tools, technologies, and strategies that help brands design out waste, rethink production systems, and build with longevity, repairability, and recyclability in mind. The section will highlight developments and news from DPPs and digital twins to on-demand manufacturing and modular design.

Circular materials: Sparxell received a €1.9 million grant from the European Innovation Council

Sparxell, a startup developing plant-based colourant technology, has been awarded a €1.9 million grant from the European Innovation Council (EIC) to tackle key technical challenges in scaling its technology.

Sparxell’s biodegradable pigments offer a sustainable and circular solution for synthetic alternatives. By transforming cellulose (from sources like wood pulp and agricultural waste) into colourants, Sparxell’s technology outperforms traditional dyes in both colour intensity and durability, while being completely non-toxic and biodegradable.

The company is approaching its first million in sales and aims to reach tonne-scale production in 2025.

Luxury fashion is one of the main industries for Sparxell, and the company is currently taking part in LVMH’s La Maison des Startups accelerator program.

Made-to-order: Luxury brand Gabriela Hearst launched a made-to-order suiting service

Luxury brand Gabriela Hearst has launched a new made-to-order suiting offering, “Tailored Bespoke”, in all of their flagship boutiques. Suits are the fastest-growing category in their ready-to-wear collections, and account for 24% of the brand’s ready-to-wear sales.

“People want things that are special and different, especially when you see this industrialization of luxury. The idea of individualization and a product that is not available everywhere. It felt natural and there was this appetite from our clients.”

- Gabriela Hearst

→ Read more in the WWD feature article

Digital Product Passport: Ask Scandinavia partners with solution provider Tree, IoDF launches a DPP, Bangladesh garment industry pilot

Digital Product Passports (DPPs) will become mandatory for fashion brands selling in the EU by 2030. But some companies are already taking the lead. From a circularity perspective, DPPs can unlock greater transparency and traceability, two critical foundations for keeping products and materials in circulation longer.

Last week, Finnish brand ASK Scandinavia launched its DPP with solution provider Tree. The brand emphasized that this is not just a regulatory move but a new standard for product communication. Tree’s platform focuses on making DPPs part of a seamless customer experience.

Meanwhile, IoDF (previously Institute of Digital Fashion) announced a new partnership with product engineering company Epam. Together, they aim to develop a DPP solution that goes beyond compliance, integrating storytelling and community-building to engage customers.

Beyond individual brands, the broader industry is also testing DPPs. The Bangladesh Garment Manufacturers and Exporters Association (BGMEA) is launching a 24-month pilot to trial DPPs with selected manufacturers. The initiative supports data collection and traceability in Bangladesh’s garment supply chain by piloting digital product passports with selected manufacturers. With 60% of exports going to the EU, the project highlights the need to align with upcoming EU standards.

Designing for circularity: The EU approved a unified way of measuring the environmental impacts of textiles and apparel

A couple of weeks ago, the EU released a unified method for calculating the environmental impacts of apparel and footwear, with the publication of PEFCR v3.1 (Product Environmental Footprint Category Rules).

What is PEFCR?

The PEFCR provides technical rules for how companies should calculate the environmental footprint of their products using life cycle assessment (LCA). It ensures that product impacts are measured consistently and comparably, which is critical for upcoming EU sustainability regulations and credible product claims.

What is new in PEFCR v3.1?

Here are a few highlights from what has been updated in the new version of PEFCR.

The latest update rewards products that are designed to last longer and be repaired. Both durability and repairability now improve the product’s environmental score. The rules also introduce new default lifespans per product category (e.g. 45 uses for t-shirts, 100 for coats), and products that exceed these baselines through better design can be scored higher.

End-of-life impacts are also calculated more consistently. Previously, incinerating garments could result in credits for energy recovery, which has now been removed. The update discourages incineration and shifts focus toward reuse and recycling.

PEFCR v3.1 also includes microfiber pollution in the environmental score. It calculates the amount of fibers released during washing and its potential impact on marine ecosystems.

The update also outlines ideas for future improvements. One focus area is understanding the real-world impact of repairability vs. durability.

Is using PEFCR mandatory for fashion brands in the EU?

PEFCR v.3.1 is available for voluntary use by companies, but its full legal enforcement within the EU will only occur once the associated legislative frameworks are officially adopted. The PEFCR v3.1 is expected to play a significant role in upcoming EU regulations, such as the Green Claims Directive and the Ecodesign for Sustainable Products Regulation (ESPR).

→ Read more about PEFCR

→ Read a simplified guide by Carbonfact

Miu Miu launched a new upcycled collection

Miu Miu has released a new upcycled collection together with a costume designer Catherine Martin. Miu Miu Upcycled was launched in 2020, and it has featured a series of collections where vintage garments are upcycled through the Miu Miu aesthetic.

→ Explore more

→ Read NSS feature article

Upcycling company Losanje won ANDAM Fashion Innovation Award 2025

French upcycling company Losanje has won the 2025 ANDAM Fashion Innovation Award for its circular solution transforming deadstock and unwanted textiles into new fabrics and products.

Losanje acts as a design and manufacturing partner for fashion brands in upcycled designs. Brands can either source textile materials through Losanje’s networks, or utilize their obsolete textiles for upcycled products. Losanje’s expertise reaches from the design and concept phase to material selection and prototyping, as well as production of the upcycled pieces.

→ Read more here

→ Discover Losanje

New study: Policy must lead the scaling of textile recycling in Europe

Systemiq, together with industry partners like Arc'teryx and Textile Exchange, has released a comprehensive new study on how to scale polyester textile recycling across Europe.

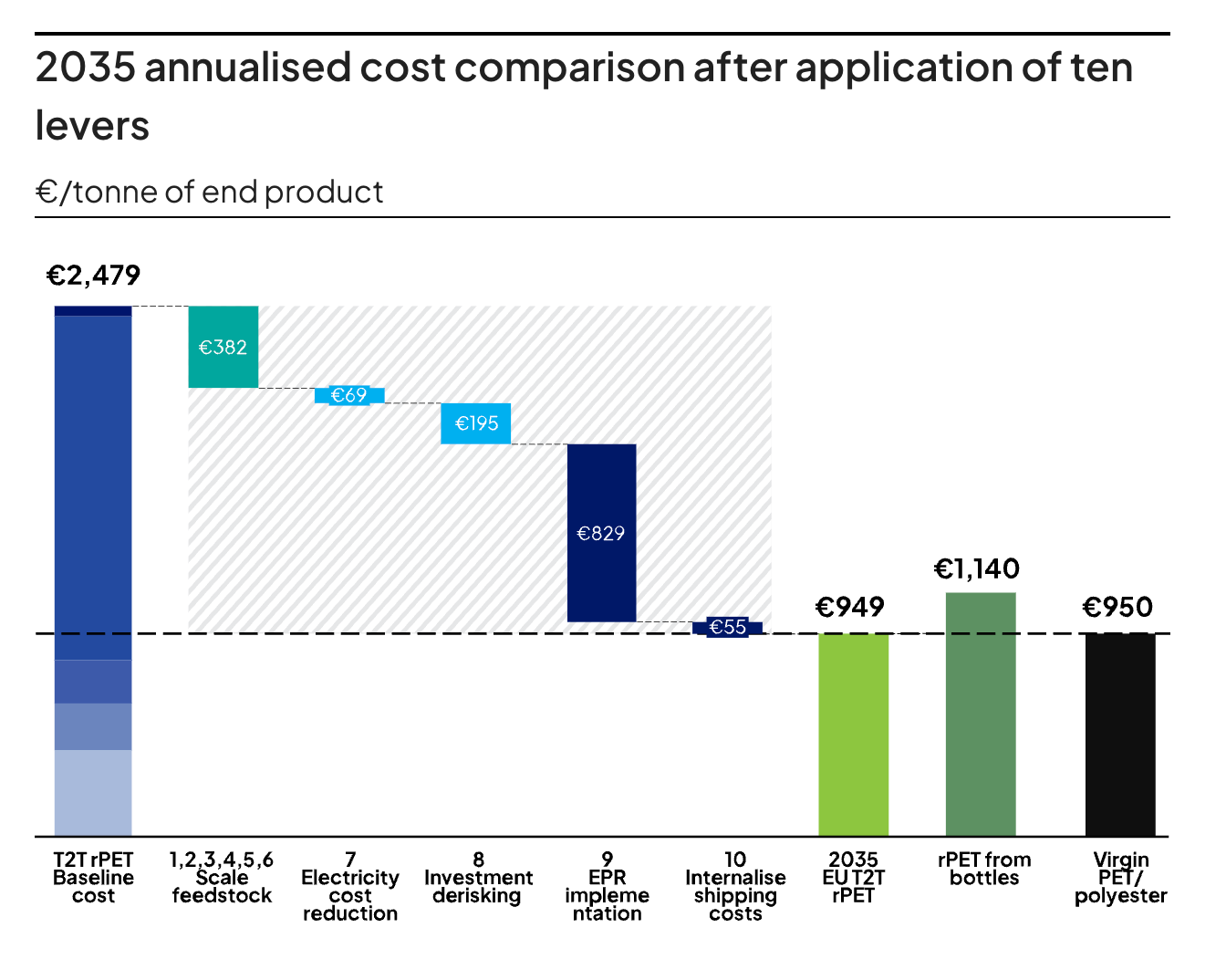

The report focuses on depolymerisation, a chemical recycling technology that can turn post-consumer polyester textiles back into high-quality fibre, with significantly lower emissions than virgin production. However, the main barrier is cost: recycled polyester from textiles is currently 2.6× more expensive than virgin polyester.

Whereas virgin polyester costs ~€950/tonne, recycled polyester’s price is ~€2,480/tonne. Currently, the industry favors recycled polyester from plastic bottles, which is priced ~€1,140/tonne.

The report outlines 10 levers to close this gap, with EPR (Extended Producer Responsibility) fees being the most critical. Systemiq’s analysis suggests EPR fees should reach ~€250/tonne by 2028 and ~€330/tonne by 2035 to cover the full cost of collection, sorting, and recycling in a scaled system. In comparison, current proposals (such as ~€120–220/tonne in the Netherlands) fall short of what’s needed to make textile-to-textile recycling viable at scale.

That is all for now, let’s hear again next week! In the meantime, let’s continue the discussion in the comments, LinkedIn, or Instagram <3

xx Tiina